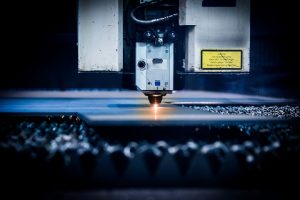

There are many chances that a printing company offer laser cutting too, which could definitely benefit your business. However, before such advantages are discussed, it is important to understand how this process actually works. Indeed, a laser is used to cut through a variety of materials, which can be achieved either through burning, melting or vaporising. The path of the beam is determined by an advanced software program, which ensures that the beam’s accuracy and speed is maintained to a safe level. The relative strength of the beam will change depending on the material that is used (i.e. a metal like steel will require a stronger beam setting). So, what are some of the advantages of your business hiring out printing companies with laser cutting in Sydney?

Accuracy

As stated before, accuracy is a big advantage! New advanced technologies mean that current techniques for laser cutting in Sydney have developed immensely, affording users greater precision with their images. The new modern machines on the market are incredibly efficient in carving small diameter holes and lines with an enhanced level of detail. This means that your images, artwork or cut-outs will benefit from a greater level of quality.

Cost

Additionally, laser cutting in Sydney is an effective method of design that brings about its own cost saving benefits. There’s no denying that the initial purchase of the machine is expensive, however, in the long term, this will be a beneficial investment. Why? Because you will be able to complete more jobs over time, earning your business more revenue, while saving you more money per unit. In addition, these machines make additional machinery obsolete, which will minimize your manufacturing costs significantly and, ultimately, boost your annual profit margins.

On top of this, these machines are particularly energy efficient, so chances are you’ll see your energy bills plummet if you swap in some of your older machinery for some up to date printers. Indeed, in the market of laser cutting in Sydney, most machines use around 10kW of power, whereas alternative methods and older machines will generally consume five times that!

Speed

Put simply, these innovative machines are faster than their alternatives. You’ll find many of your jobs are being completed in a shorter time frame, affording you the opportunity to take on more work. What does this do? Well, it saves you money, time and resources, meaning you can streamline your costs, charge lower prices and undercut your key competitors.

Cleaner production

Traditional methods will leave some waste afterwards. Indeed, mechanical strategies can often leave scraps of metal long after the project is complete, which can become an annoyance in the working environment. However, firms that offer laser cutting in Sydney will affirm that there is a much lower level of contamination surrounding the workplace. This is because the heat created from the machine is contained, generating less overflow of melted liquid. As a manufacturer, you don’t want to be devoting hours to cleaning your work station.

Maintenance

Metal carving machines are subject to wear and tear; however, these machines are generally quite strong and durable. You’ll find that the running maintenance costs will be reduced and that the chances of you having to replace your machine are far less likely.

Safety

Laser cutting in Sydney is a process governed by strict regulations and safety measures. On top of this, the design of the machines ensures that the beam never actually touches the material physically. In fact, the beam is sealed in a light box and only causes heat. Subsequently, this heat creates the melting of the material, which in turn creates the image or cut-out desired.